PL85 Moomprimer

Description

PL85 Moomprimer is a solvent based, high viscosity, full-bodied polymer modified bituminous coating, without fillers, pigments, lead and cobalt with excellent adhesion which is used as a top coat along with PY95 and PB285 Moomprimers or as a coating layer alone.

Functions

Control and protection of metal and concrete against most corrosive agents.

Typical Uses

PL85 Moomprimer is used as a top coat or coating where a cold applied, effective, protective, weatherproof and corrosion resistant coating is needed. For instance, exposed and buried metal and concrete structures including:

✔ Metal Structure

Used as a top coat, on PY95 Moomprimer with the purpose of coating (rustles or rusty) metal surfaces, eliminating the sandblast process. It protects metal surfaces in severe climate conditions and against corroding agents and humidity:

✔ Steel Structure & Industrial Shed

✔ Steel Column Base & Base Plate

✔ Steel Reinforcement

✔ Metal Profile & Steel Façade Frames

✔ Metal Tank to hold Acid & Alkali & Industrial Effluent

✔ Mechanical Installation & Chiller

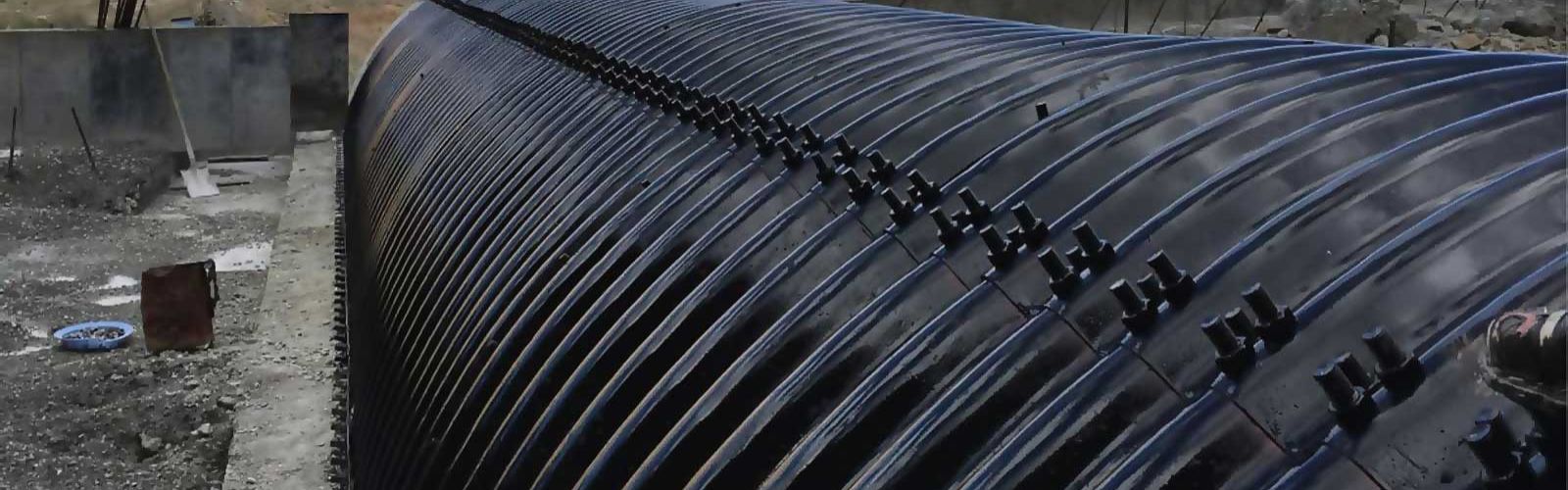

✔ Water, Sewage, Oil & Gas Pipelines

✔ Corrugated Steel Plate & Sheet

✔ Metal Power Towers

✔ Metal Bridges

✔ Metal Silos

✔ Concrete Structure

Used as a top coat, on PB285 Moomprimer with the purpose of sealing concrete surfaces:

✔ Retaining Wall & Shotcrete & Shear Wall

✔ Concrete Bridge Deck & Bridge Foundation

✔ Exposed & Buried Concrete Tanks & Pipes

✔ Subway Tunnel & Shaft Wall

✔ Power Transmission Tower Foundation

✔ Concrete floor & Foundation

✔ Septic Tanks

Advantages

Licenses

1. Ministry of Petroleum (Iran) Vendor2. The Institute of Standards and Industrial Research of Iran

3. Research Institute of National Iranian Petroleum Industry Oil Company

4. National Iranian Gas Company

5. Road, Housing and Urban Development Research Center

6. Tehran College of Electrochemistry

7. Amir Kabir University of Technology

8. Razi Metallurgical Research Center

9. Iranian Ministry of Roads and Urban Development Laboratory

10. Ministry of Defense

Technical Data

Coverage

⦁ Suggested Thickness in Different Applications:

✔ Metal structure: 50µ∼ 80µ

✔ Concrete structure: 500µ∼ 1000µ

⦁ Coverage Surface per Desired Thickness:

✔ Metal Structure: 5-3 Square Meter

✔ Concrete Structure: 2-1 Square Meter

Implementation Method

Surface preparation

Surfaces onto which the PL85 Moomprimer is to be applied as single-layer coating, must be clean from loose layers, humidity, soil, grease or oil stain. PL85 Moomprimer can be applied on rust without requiring rust removal. Repair surface cracks with suitable concrete repair products to create a healthy surface.

There is no need for special preparations such as sandblasting of the surfaces on to which the PL85 Moomrimer is to be applied as topcoat.

Metal Structure: On metal surfaces, 24 hours after implementing the first layer of PY95, the PL85 Moomprimer is applied on the surface. Protect the layer from rain and getting wet for 24 hours.

Concrete Structure: On concrete surfaces, 24 hours after application the first layer of PB285, the PL85 Moomprimer is applied on the surface. Protect the layer from rain and getting wet for 24 hours.

Single-layer coating: If PL85 Moomprimer is applied as a single-layer coating, it shall be applied using suitable tools and observing all necessary requirements.

Application of PL85 Moomprimer